or start from open source methods. Learn more about OneLab softwareUse OneLab

Peptide SPE Method Development

This basic method provides the core methodology for translating a workflow into OneLab-executable script(s) as an attempt to fully or semi-automate a specific procedure. It demonstrates the benefits of automation and highlights OneLab capabilities and best practices to promote solution adoption, helping transition from manual to a more automated approach. It can be used alone or serves as a building block for a more complex workflow and is easily adaptable to users' requirements.

Overview

┛This method showcases an SPE-based Sample Prep┏

Peptide Separation Technology (PST) on the Andrew+ Pipetting Robot

LC-MS/MS analysis of biological samples requires extensive sample clean-up procedures to remove matrix components that may adversely affect the quantitation of the target analyte. Peptide and protein-based therapeutics bring their own specific method development challenges which can be time-consuming and tedious.

Here we present an automated Solid Phase Extraction (SPE) protocol using the Oasis Peptide Method Development 96 well μElution Plate for developing a reproducible and robust extraction method for peptides. The 96-well plate format contains six rows each of two Oasis mixed-mode, ion-exchange chemistries: a Mixed-mode Anion exchanger (MAX), which is ideal for peptides with pKa >2-8 and a weak cation exchanger (WCX), which is usually preferred for peptides with pKa >10. Sample preparation method development can be quickly and easily achieved with the use of a single SPE protocol.

Automation of this SPE sorbent selection protocol using the Andrew+ Pipetting Robot makes the entire process rapid, reproducible, and robust with minimal manual intervention. Additionally, automating the approach enables multiple variables (e.g., different compositions for wash and elution solvents or variable vacuum settings, for better recoveries) to be tested in a logical and reproducible manner.

Method Development Protocol for SPE of Peptides from Biological Matrices

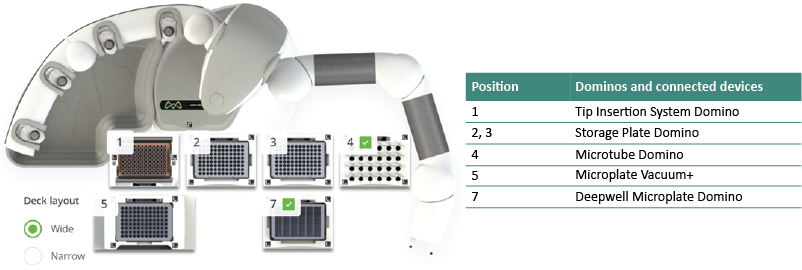

All the steps in the SPE sorbent selection method development are automated by the Andrew+ platform (Figure 1). This includes sample dilution, loading, equilibration, washing, elution, post-spiking (reference samples), as well as controlling the vacuum of the SPE manifold (except for manually replacing the waste collection plate with the sample collection plate in the vacuum manifold before the elution step). Vacuum control provides stepwise and controlled pressures (pressure gradient) particularly useful for peptide SPE where controlling the rate/time of adsorption and elution can be critical for a good recovery. The SPE-extracted samples in this example were quantified by LC-MS/MS.

Figure 1: Andrew+ deck layout for automated Oasis PST SPE protocol for therapeutic peptides.

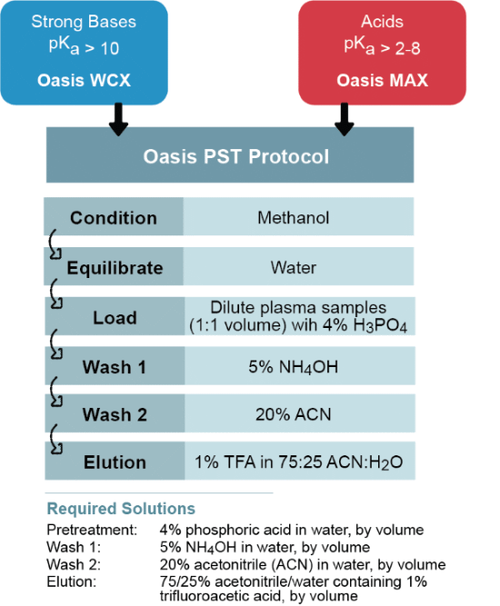

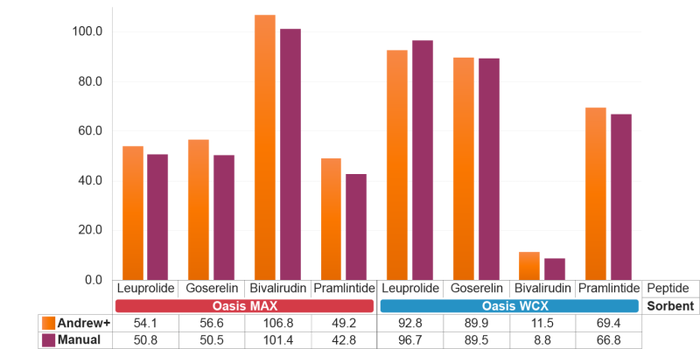

PST (Peptide Separation Technology) workflow and reagents used for the solid-phase extraction of peptides from plasma samples are shown in Figure 2. In this protocol, the automation of the sorbent selection method using the Oasis Method Development 96-well μElution Plate is demonstrated by extracting four analytes Leuprolide, Goserelin, Pramlintide and Bivalirudin from spiked human plasma samples. Peptides produce good analyte recovery specific to one of the two Oasis mixed-mode sorbent chemistries WCX and MAX depending on the characteristics of the peptide. In this case, Leuprolide, Goserelin, and Pramlintide showed good recoveries using the WCX sorbent, whereas Bivalirudin showed better recovery using the MAX sorbent.

Figure 2: Oasis PST SPE method Workflow.

To demonstrate the reproducibility and robustness of the method transfer from a manual process to automation, this protocol was performed both manually and also automated using the Andrew+ robot. The results generated with manual sample treatment vs automated process shown in Figure 3 demonstrate that this protocol can be adapted to the Andrew+ robot with ease and reliability.

Figure 3: Comparison of peptide recoveries on different sorbents (Oasis MAX and WCX) with manual vs automated process.

ORDERING INFORMATION

Andrew+ System Components: Dominos, Devices, Electronic Pipettes & Tips

- Deepwell Microplate Domino | p/n 186009597

- 2x Storage Plate Domino | p/n 186009596

- Microtube Domino | p/n 186009601

- Tip Insertion System Domino | p/n 186009612

- Microplate Vacuum+ | p/n 176004579

- IKA VACSTAR control vacuum pump | p/n 0020109375 for EU/CH, 0020109376 for the US, 0020109377 for the UK

- Andrew Alliance Bluetooth Electronic Pipette, 1-ch 300 μL | p/n 186009606

- Andrew Alliance Bluetooth Electronic Pipette, 8-ch 300 μL | p/n 186009607

- Sartorius, Optifit Tips, 5-350 μL | p/n 700013297

Consumables & Other Systems

- Oasis Peptide Method Development 96-well μElution plate, 2 mg sorbent/well | p/n 186004713

- Waters QuanRecovery™ 700 µL 96-well plate | p/n 186009185

- Agilent 6-column reagent reservoir | p/n 201284-100

- Fisherbrand™ Premium 1.5 mL microtube | p/n 11926955

- Falcon® 50 mL conical centrifuge tube | p/n 352070

- Waters silicone/PTFE cap mat for 96-well plate, 7 mm round wells | p/n 186006333

- ACQUITY UPLC Peptide CSH C18 column, 130 Å, 1.7 μm, 2.1x50 mm | p/n 186006936

- ACQUITY Premier LC system

- Xevo TQ-XS Triple Quadrupole Mass Spectrometer

Protocols

Contact info

This is an open access protocol distributed under the terms of the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original author and source are credited.

This is an open access protocol distributed under the terms of the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original author and source are credited.