or start from open source methods. Learn more about OneLab softwareUse OneLab

Automated mAb Subunit Generation

This advanced method offers an end-to-end solution developed around an advanced application, a specialized kit, or an analytical system. It delivers complete functional, ready-to-use protocols that are qualitatively and quantitatively assessed for consistency, executability, and repeatability, usually without needing to make any changes. It operates per batch size and is scalable to accommodate changing requirements.

Overview

Introduction

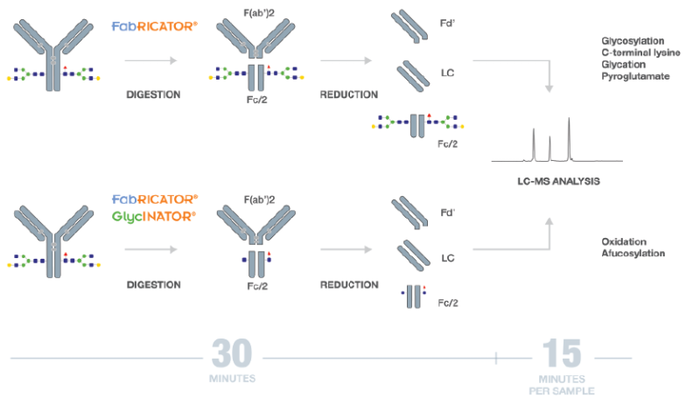

Monoclonal antibodies (mAbs) and other IgG-based biopharmaceuticals are increasingly entering clinics and improving patients’ quality of life. The inherent heterogeneity of such biologics requires detailed characterization by liquid chromatography and mass spectrometry (LC-MS). While bottom-up peptide mapping is still the gold standard for the analysis of critical quality attributes, such approaches are resource and time-intensive in both data acquisition and analysis. Top-down and middle-down approaches are therefore increasing in popularity. Antibody subunit analysis has become a widely accepted analytical strategy for the rapid characterization of therapeutic antibodies and related products. The FabRICATOR® (IdeS) enzyme specifically digests IgG below the hinge, which after the reduction of disulfide bonds yields antibody fragments of 23-25 kDa that are amenable to high-resolution mass spectrometry. The FabRICATOR-based middle-level LC-MS workflow, therefore, enables confirmation of sequence identity as well as analysis of multiple antibody quality attributes, including glycosylation, glycation, pyroglutamate formation, and C-terminal lysine clipping (Figure 1, top).

Figure 1: Workflow overview. mAbs are digested with FabRICATOR and disulfide bonds are reduced to yield subunits suitable for LC-MS analysis of many different critical quality attributes (top). To remove the heterogeneity caused by the Fc glycosylation, the GlycINATOR endoglycosidase can be added to the same reaction (bottom).

While being a critical quality attribute in itself, the heterogeneity of the Fc glycosylation profile can also mask other modifications that might be difficult to quantify on a glycosylated Fc/2 fragment. GlycINATOR® is a highly efficient, IgG-specific endoglycosidase that can easily remove Fc glycans on mAbs. The enzyme is compatible with FabRICATOR digestion and can be added to the same reaction of a combined digestion/deglycosylation (Figure 2, bottom). This allows for a simplified analysis of modifications such as methionine oxidations that commonly occur on the Fc fragment. Furthermore, due to the fact that GlycINATOR cleaves Fc glycans in the chitobiose core and leaves the reducing end N-Acetylglucosamine attached to the protein, this sample preparation also provides a simple approach for the analysis of afucosylation.

Here, we describe protocols for the automation of sample preparation using the Andrew+ Pipetting Robot and OneLab cloud-native software.

Experimental Procedure

The increase in samples originating from process development, stability studies, clone selection, and other high-volume applications is causing a demand for less manual labor in sample preparation and analysis. This conflict could potentially limit the pace of therapeutic drug development programs and requires solutions that enable automated and robust sample handling and analysis. The middle-level analysis is well suited for this type of assay as it does not necessitate prolonged, multi-step sample preparation which can be difficult to make reproducible and might not be amenable to automation.

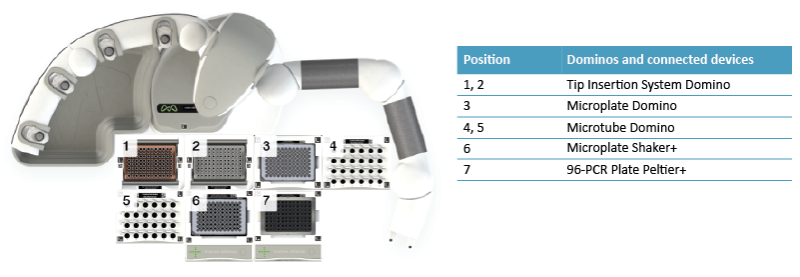

Here, the sample preparation consists of a single one-pot reaction. To this end, 50 μg mAb samples are dispensed into individual wells of a 96-well plate and combined with 50 units of FabRICATOR enzyme and 50 mM DTT in a total reaction volume of 50 μL 20 mM Tris, pH 7.5. If removal of the Fc glycans is desired, an additional 50 units of GlycINATOR is added to the same reaction. The reaction is mixed by shaking the plate for 45 seconds at 1500 rpm. Reactions are then incubated at 37°C for 30 minutes and transferred to an autosampler-compatible 96-well plate in preparation for analysis by LC-MS. The sample preparation protocol can either be performed manually or fully automated using the Andrew+ Pipetting Robot. An overview of the Andrew+ configuration for this assay is shown in Figure 2.

Figure 2: Andrew+ Domino configuration for automated sample preparation of mAbs for middle-level analysis.

Considerations

1- Reaction Buffers

- Both GlycINATOR and FabRICATOR enzymes are active in a broad range of neutral pH buffers. The assay can therefore also be performed in reaction buffers other than 20 mM Tris, pH 7.5

2- Incubation Time

- The enzymes are very specific and do not over-digest even with prolonged incubation times or increased enzyme amounts. There is therefore no need to stop the reaction.

3- Analysis by LC-MS

- The 350 μL 96-round well collection plate can be placed directly into the autosampler of a Waters LC-MS system. To that effect, the plate was sealed using a polypropylene cap mat to avoid contamination and evaporation.

ORDERING INFORMATION

Andrew+ System Components: Dominos, Devices, Electronic Pipettes & Tips

➤ Sample Preparation for mAb Subunit Analysis

- Microplate Domino | p/n 186009600

- 2x Microtube Domino | p/n 186009601

- 2x Tip Insertion System Domino | p/n 186009612

- 96-PCR Plate Peltier+ | p/n 176004584

- Microplate Shaker+ | p/n 176004577

- Andrew Alliance Bluetooth Microplate Gripper | p/n 186009776

- Andrew Alliance Bluetooth Electronic Pipette, 1-ch 10 µL | p/n 186009769

- Andrew Alliance Bluetooth Electronic Pipette, 1-ch 300 μL | p/n 186009606

- Optional - Andrew Alliance Bluetooth Electronic Pipette, 8-ch 300 μL | p/n 186009607

- Sartorius, Optifit Tips, 0.1-10 µL (x9) | p/n 700013293

- Sartorius, Optifit Tips, 5-350 μL (x14) | p/n 700013297

➤ Sample Preparation for mAb Subunit Analysis, with deglycosylation

- Microplate Domino | p/n 186009600

- 2x Microtube Domino | p/n 186009601

- 2x Tip Insertion System Domino | p/n 186009612

- 96-PCR Plate Peltier+ | p/n 176004584

- Microplate Shaker+ | p/n 176004577

- Andrew Alliance Bluetooth Microplate Gripper | p/n 186009776

- Andrew Alliance Bluetooth Electronic Pipette, 1-ch 10 µL | p/n 186009769

- Andrew Alliance Bluetooth Electronic Pipette, 1-ch 300 μL | p/n 186009606

- Optional - Andrew Alliance Bluetooth Electronic Pipette, 8-ch 300 μL | p/n 186009607

- Sartorius, Optifit Tips, 0.1-10 µL (x9) | p/n 700013293

- Sartorius, Optifit Tips, 5-350 μL (x15) | p/n 700013297

Reagents & Chemicals

- FabRICATOR® enzyme, 2000 Units by Genovis | p/n A0-FR1-020

- DTT (1,4 Dithiothreitol) by G-Biosciences | p/n 786-077 or equivalent

- 20 mM Tris, pH 7.5

- Optional - GlycINATOR® enzyme, 2000 Units by Genovis | p/n A0-GL1-020

Recommended Consumables

- Fisherbrand™ Premium 1.5 mL microtube | p/n 11926955

- Eppendorf twin.tec® 96-well skirted LoBind® PCR plate | p/n 0030129555

- Waters 350 μL 96-round well collection plate | p/n 186002643

- Optional - Waters polypropylene cap mat for 96-well plate, round wells | p/n 186002483

Protocols

Contact info

This is an open access protocol distributed under the terms of the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original author and source are credited.

This is an open access protocol distributed under the terms of the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original author and source are credited.